Press Fit Pins Sheet Metal

Die protector eliminate unsightly tool marks on your stainless steel.

Press fit pins sheet metal. Top reasons to choose us. Mike brieschke vice president of sales at aries engineering says a 0 25 inch diameter metal dowel that is press fit into a mild steel hole usually has an interference of 0 0015 inch. Parts in noncritical assemblies tend to have looser tolerances. We engineer manufacture press brake dies to fit your needs.

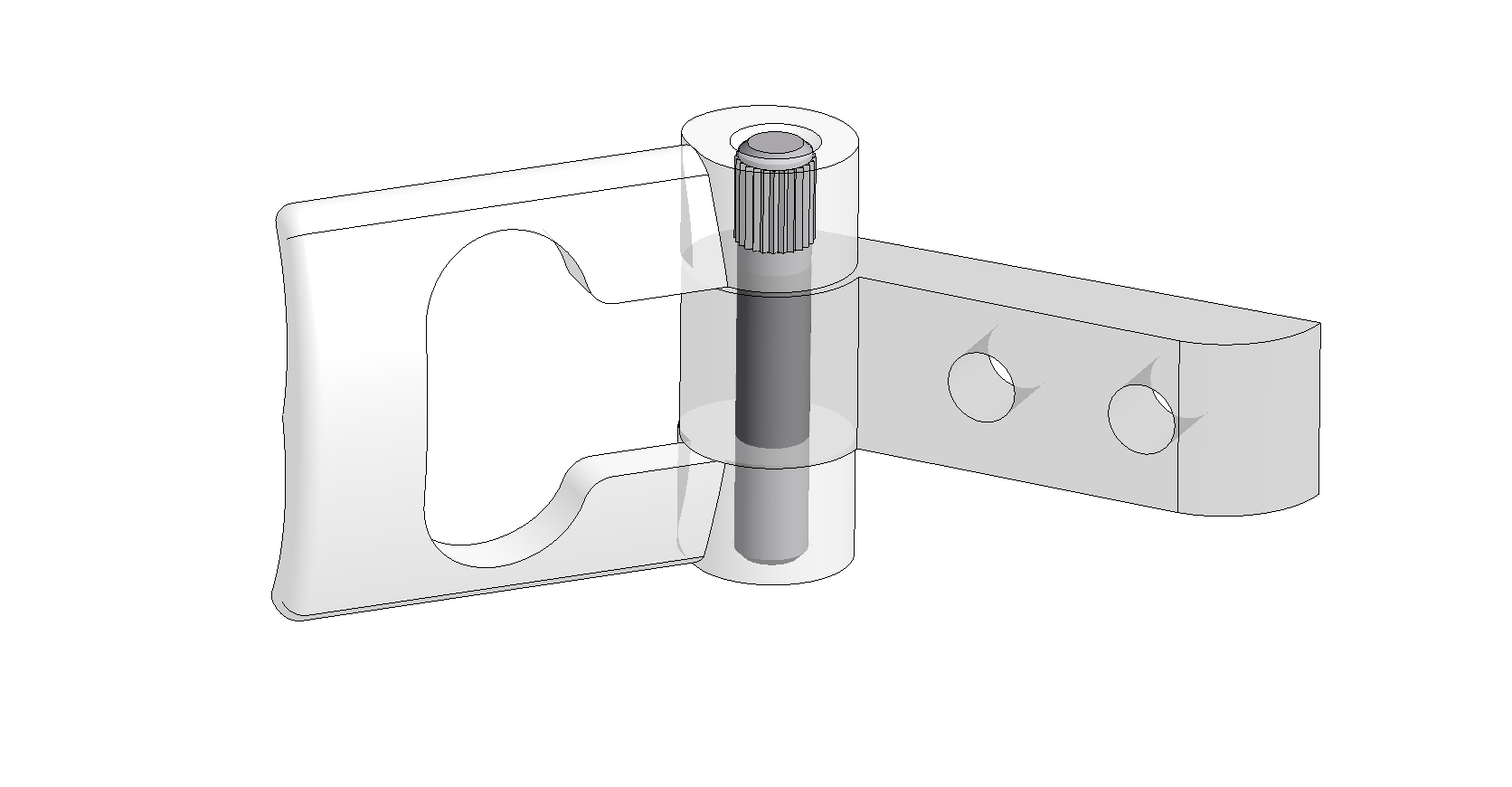

A common method of self locating parts in machine assemblies is to use dowel pins which can then either be used strictly as a locating feature to hold parts in the correct place during assembly with screws or can be used on their own for press fit assembly. Pinpoints a fastener s resistance to being pulled through the metal sheet when applying a clamping torque. These fasteners are ideal for applications where a thin sheet requires load bearing threads but still must remain smooth with no protrusions on either surface. Pemsert self clinching flush nuts are designed to be completely flush in sheets as thin as 060 1 5mm.

If you must use two press fit pins be certain to use gd t tolerancing with the first hole as the datum for the second hole to minimize error between the two features. A press fit ensures that the pin will remain embedded in the base material unless removed. We generally recommend the below tolerances when inserting a pin. Concealed head standoffs types csos css.

With a press installation is relatively simple. Even better use only one interference fit and align the parts with a slip fit second pin. Pem self clinching concealed head standoffs install permanently in steel or aluminum sheets as this as 062 1 6mm. A slip fit allows objects to be easily removed from the designated hole but ensures a firm fit.

Never more than two pins per assembly operation. This feature allows the side of the sheet opposite installation to remain smooth and untouched. Standoffs for sheet metal. Family owned for 98 years.

Second rule of press fits. The two most common types of dowel pin callouts are press fit and slip fit. To remove thread a screw or tool into the tapped hole then pull the pin out. We are now in our fourth generation of providing the best product and great service.

The benefits of self location aren t just for welded or sheet metal parts. The clinch design provides high strength in sheets as thin as 031 0 8 mm.