Pro Rib Steel Roofing Purlin Spacing

Use 5 purlin spacing maximum install panels note.

Pro rib steel roofing purlin spacing. 403 279 2766 skylight chimney cut opening in roof panel. Place the first screw about 7 inches from the bottom and each subsequent screw about 18 to 24 inches apart along the vertical run. Lay down the first roof steel panel squaring it with the mason line. Without a set of blueprints with a pe s seal you have no option but to follow the inspectors gig.

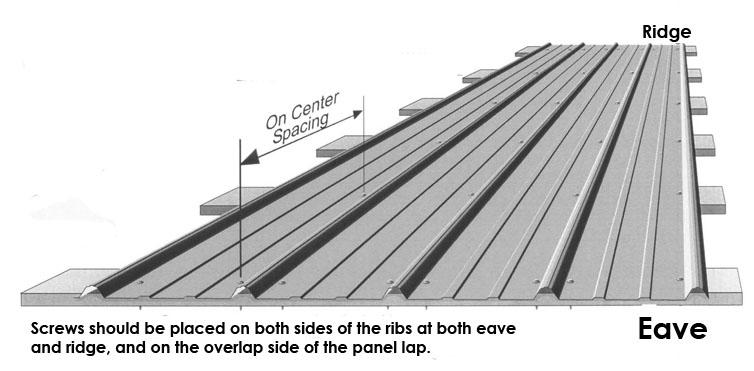

Suggested line spacing is one foot beyond 3 panels wide or about 10 feet. Do all roofing projects require purlins. Install panels on solid decking install plywood deck. Rib of roof panel with screws on every rib along both sides of rib.

At bottom of opening slit panels or. For solid decking use 14 x 1 mp screws. Roof sheathing consists of premium pro rib steel panels attached to the top edge of roof purlins in accordance with manufacturer s specifications or as shown on design drawings. Check for square by measuring the distance from the installed panel edge to the chalk line at both the eave and ridge.

Install the roofing screws vertically along each rib in the panel. This option not recom mended for roofing a heated space with no insulation or vapor barrier. The roof panels are installed similar to the wall panels in layout. For 2 x 4 purlins use 9 x 1 woodfast screws fastener spacing panel screws per lineal foot of roofing 12 4 5 18 3 0.

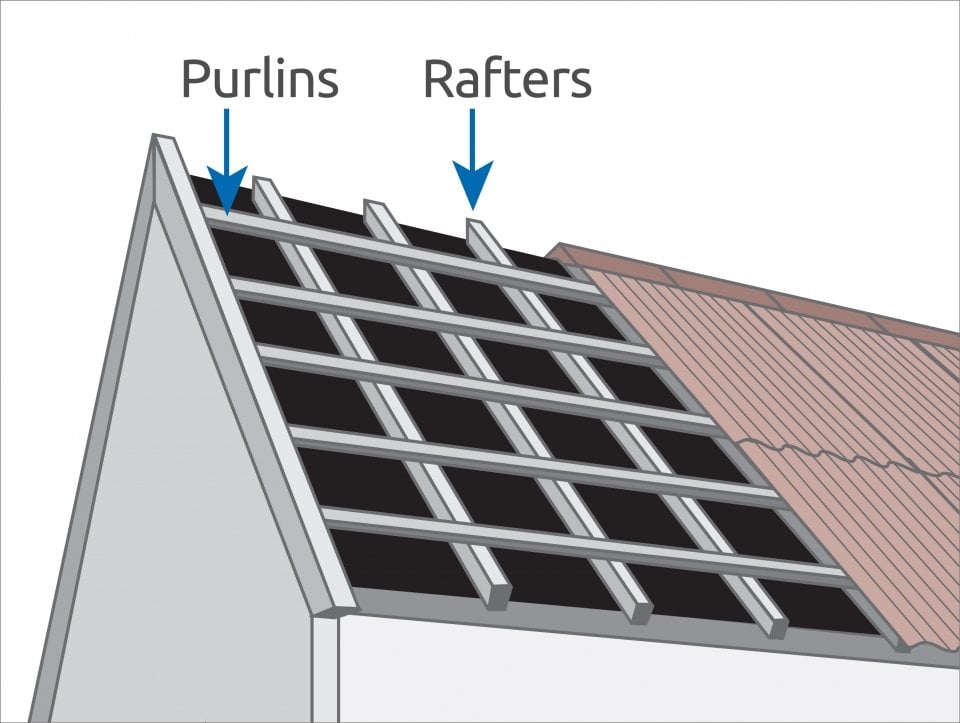

Nominal thickness of 0180 g 100 galvanized coating plus zinc phosphate per astm 653. Fastener spacing may not exceed 1 1 2 38mm. Maximum purlin spacing for roof 5 on center option 1. Purlin spacing is dependent on profile of the metal and gauge plus snow and wind load plus what the rafters are designed to carry.

All intermediate fasteners can be. Purlins are non pressure treated 1 x 4 x 12 lumber that is installed on to the roof in a specific layout pattern and screw pattern. Install panels direct ly to wooden framing. The purpose of the purlins is to provide a solid foundation for the metal roofing panels and trim to be screwed to.

Install emseal closure 3 inches back from metal. Quantity will vary based on spacing of fastener rows. We do recommend it however. Keep metal roofing back 3 inches.

Secure the screws but do not overtighten. Cut the first rib off leaving of rib on the first roof sheet of roof steel. Using screws fasten roof at top and bottom of the sheet in the flat next to each rib. Since direct contact between pressure treated lumber and metal roofing must be avoided in order to prevent potential corrosion.

The washer under the screw head should seal to the surface of the panel without bulging or shifting.