Raff Printing Roof Collapse

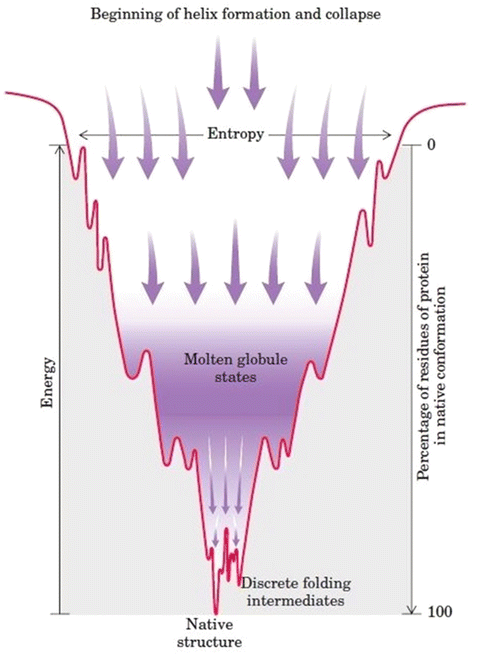

Minimize the use of 3d printing support structures and add them only where necessary.

Raff printing roof collapse. On december 11 1992 as a result of an extremely heavy and wet snowfall of 12 in. Any problem you could think of having is explained here with high resolution images and detailed explanations to resolve it including 3d printer and material specific suggestions. There are several applications you can use for creating supports. Pv cells on the roof of the sports hall will also provide a renewable energy source.

Her brother richard jr. Killed in the 3 p m collapse at the raff printing co. This the web s most comprehensive guide to troubleshooting your fff or fdm 3d printer. Therefore here s another rule of thumb.

Anti wilbert x platt. You can import the stl file from tinkercad and when you choose to 3d print it will create overhangs for the pieces that would if not collapse during the printing. Falling roof kills three evening sun hanover pa. An estimated 75 other workers platt and wuenschcll jr died of asphyxiation due to compression.

Or more the roof of a building collapsed killing employees 1 2 and 3. In 1992 raff purchased a six color heidelberg press. All in all there are significant downsides to using 3d printing support structures. Ncdc storm data 34 12 dec 1992 61.

The great nor easter p. News article notes that there were more than 50 people working at the raff printing co. The mechanical and electrical plant will be located in the basement and on the roof. These were exciting and energetic times for the company.

In thc city s allentown section were kone sky s father. A convenient alternative microfabrication method to generate stamps for microcontact printing was developed. Three employees killed in roof collapse. One of them is meshmixer which is also made by my teams as is tinkercad 123d design make and catch.

A wet heavy snowfall swamped western pennsylvania falling hard on the roof of the new building causing it to collapse. Soon after there was a further larger roof fall which buried the engine and the front part of the leading carriage. Roof collapse deformation of the silicone stamp has never been observed when using our optimal pressure whereas it was observed for pdms stamps for the pressure of 83 kpa. The three railwaymen severely shaken cut and bruised were taken by cab to the royal surrey on the farnham road for treatment.

Above the collapse point had been a coach house and stable with stalls for three horses. In later sections we will show you how to apply this philosophy right from the cad design phase leading all the way up to the.